The Versatile Graphite: Beyond the "Lead" in Pencils

The so - called "lead" in pencils is actually graphite, a form of carbon, not lead metal. This common misnomer has persisted over time, likely due to the historical association of the writing material with the metallic lead's similar appearance when used for marking. Graphite has a variety of other uses beyond being the writing core in pencils. When you think about a simple pencil, the smoothness with which the graphite leaves a mark on paper is a testament to its unique properties. The graphite core is carefully crafted, often mixed with clay to achieve different degrees of hardness, from the very soft 9B pencils used by artists for bold and dark sketches to the hard 9H pencils favored for technical drawing where fine, light lines are required.

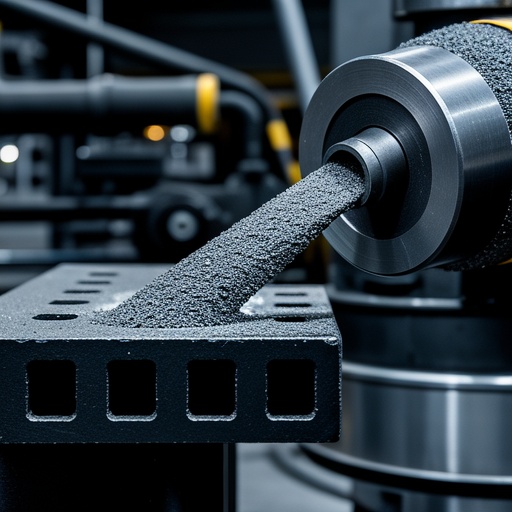

First, in the field of industry, graphite is widely used as a lubricant. Its layered structure allows the layers to slide over one another easily, which gives it excellent lubricating properties. This unique atomic arrangement is like a stack of thin sheets that can glide past each other with minimal resistance. It can be used in high - temperature environments where traditional oil - based lubricants would break down. For example, in heavy - duty machinery, such as large - scale mining equipment and industrial presses, graphite lubricants can reduce friction between moving parts, extend the service life of the equipment, and improve operational efficiency. In a mining operation, the massive crushers and conveyors are constantly under stress. The moving parts, such as gears and bearings, generate a significant amount of heat and friction. Traditional lubricants may evaporate or lose their viscosity at the high temperatures generated, leading to increased wear and tear. Graphite lubricants, on the other hand, can withstand these extreme conditions. They form a thin, protective layer between the moving surfaces, preventing direct metal - to - metal contact and reducing the energy wasted in overcoming friction. This not only saves on maintenance costs but also increases the overall productivity of the mining operation.

Graphite is also used in the manufacture of electrodes for electrolysis processes. In the production of aluminum, graphite electrodes are used in the electrolytic cells. During the electrolysis of alumina to produce aluminum, the graphite electrodes conduct electricity and participate in the chemical reactions. The high electrical conductivity and chemical stability of graphite make it an ideal material for this application. The Hall - Héroult process, which is the primary method for aluminum production, relies heavily on graphite electrodes. These electrodes are immersed in a molten electrolyte containing alumina. When an electric current is passed through the electrolyte, the graphite electrodes act as a conduit for the electrons, facilitating the reduction of aluminum ions to metallic aluminum. The chemical stability of graphite is crucial here because it can withstand the highly corrosive environment of the electrolytic cell. Over time, the graphite electrodes do gradually wear down, but their long - lasting nature and ability to maintain their performance make them the material of choice for this large - scale industrial process.

Another industrial application of graphite is in the production of brake linings. In the automotive and aerospace industries, reliable braking systems are of utmost importance. Graphite is added to brake linings due to its excellent heat - dissipation properties. When a vehicle brakes, a large amount of kinetic energy is converted into heat. If this heat is not dissipated effectively, it can cause the brake components to overheat, leading to reduced braking performance and potential safety hazards. Graphite helps to absorb and disperse this heat, ensuring that the brake linings maintain their friction coefficient and operate safely. For example, in high - performance sports cars that can reach very high speeds, the braking systems are under extreme stress. The addition of graphite to the brake linings allows these vehicles to stop quickly and safely, even after repeated high - speed braking maneuvers.

Second, graphite has important applications in the nuclear industry. It can be used as a neutron moderator in nuclear reactors. In a nuclear fission reaction, neutrons are released at high speeds. To sustain the chain reaction, these neutrons need to be slowed down. Graphite has the ability to slow down neutrons through elastic collisions, allowing them to be more readily absorbed by uranium nuclei, thus maintaining the nuclear fission process. In a nuclear power plant, the reactor core is a complex and highly regulated environment. The graphite moderator is carefully designed and placed within the core to ensure that the neutron speed is optimized for the fission reaction. The quality and purity of the graphite are of critical importance. Any impurities in the graphite could potentially absorb neutrons, disrupting the chain reaction and reducing the efficiency of the reactor.

Additionally, graphite is used in the production of refractory materials. Due to its high melting point and good thermal stability, it can be added to refractory bricks and other high - temperature - resistant materials. These refractory materials are used in furnaces, kilns, and other high - temperature industrial facilities to line the interior and protect the structure from the extreme heat. In a steel - making furnace, for instance, the temperatures can reach well over 1500 degrees Celsius. The refractory bricks lined with graphite can withstand these intense temperatures without deforming or melting. This not only protects the furnace structure but also ensures that the steel - making process can be carried out efficiently. The graphite in the refractory materials also helps to improve the thermal conductivity, allowing for more uniform heating within the furnace and better control of the steel - making process.

Graphite also finds applications in the electronics industry. It is used in the production of batteries, specifically in lithium - ion batteries. The graphite anode in these batteries plays a crucial role in storing and releasing lithium ions during the charging and discharging cycles. The unique structure of graphite allows it to intercalate lithium ions, providing a stable and efficient way to store electrical energy. This is why lithium - ion batteries, which are widely used in portable electronics such as smartphones, laptops, and electric vehicles, can offer high energy density and long - lasting performance. As the demand for more powerful and longer - lasting batteries continues to grow, the quality and properties of the graphite used in battery production are constantly being improved through research and development.

In the field of aerospace, graphite - reinforced composites are used to make various components. These composites combine the lightweight properties of graphite with the strength of other materials. For example, in aircraft wings, graphite - reinforced composites can reduce the overall weight of the aircraft, leading to improved fuel efficiency. The high strength - to - weight ratio of these composites also allows for more complex and aerodynamic wing designs. In addition, graphite's resistance to high temperatures makes it suitable for use in the heat shields of spacecraft. During re - entry into the Earth's atmosphere, spacecraft experience extremely high temperatures. Graphite - based heat shields can protect the spacecraft and its occupants from the intense heat, ensuring a safe return.

In conclusion, graphite, the "lead" in pencils, has far - reaching applications in industry, nuclear energy, high - temperature material production, electronics, aerospace, and many other fields. Its unique properties, such as its layered structure, high electrical conductivity, thermal stability, and ability to moderate neutrons, make it an indispensable material. The versatility and importance of graphite in various fields demonstrate how a seemingly simple material can have a profound impact on modern technology and our daily lives. As research continues, it is likely that even more applications for graphite will be discovered, further expanding its already extensive list of uses.